When ships dock, fenders in port are big buffer devices. They are usually made of rubber, foam, or inflatable materials that soak up the impact energy. This keeps the ship’s hull and the port’s buildings (piers, quays) from being damaged. They work like big shock absorbers to make sure that ships can safely and quickly dock by reducing the forces of collisions and protecting against structural damage, oil spills, and delays in operations. They can also adjust to varied sizes of ships and sea levels.

Table of Contents

Why Do We Need Fenders in Port?

All vessels must berth at authorized sites. During this operation, the vessel must place itself in a precise spot to complete its mission. At the same time, the crew must consider the available space and other aspects of the pier, harbor, dock, piers, shoreline, and so on. When a vessel is anchored, it can be secured by mooring buoys.

As a result, even if the vessel is moving at a glacial pace, there is a significant risk of contact or collision with the harbor or other structures. When a vessel is anchored at a mooring, the chance of contact remains significant. However, a ship’s speed is zero after docking or mooring. However, the nature of the waters is extremely dynamic.

Currents, tides, and waves all contribute to continuous motion. As a result, even non-floating vessels may occasionally make contact with shore buildings. Furthermore, different vessels fulfill distinct functions at breakwaters, piers, docks, harbors, or ashore. As a result, individual boats are more likely to make direct contact with one another.

In contrast, as a vessel enters a port or harbor with heavy traffic, the danger of colliding with another vessel increases. Furthermore, two vessels can be moored together for a variety of purposes, including refueling or cargo transshipment, often known as ship-to-ship transfer (STS).

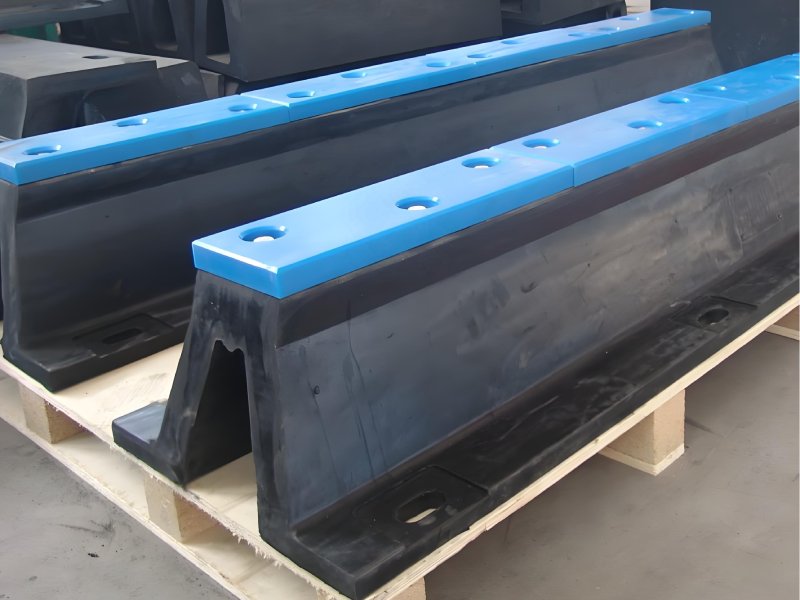

Thus, harbor fenders arose from this need. You can see these rubber fenders in a variety of ports. Common fenders in port include arch rubber fenders. For the same reason, many different types of marine fenders can be utilized for small speedboats to enormous cargo ships. These rubber maritime fenders shield the hull structure from localized crashes and impact.

Factors To Consider When Selecting A Fender

A fender built for one use may not be suitable for another. It is consequently dependent on the type and purpose of the vessel. As a result, the selection of fenders for a specific site and operation is determined by a number of factors.

Vessel Type and Operating Profile

The first and most important input is the vessel type and how it will use the berth:

- Small boats and fishing vessels: Often use simple D-type or cylindrical rubber fenders on piles or quay walls.

- General cargo and container ships: Require higher energy absorption with controlled reaction. Cone fenders, cell fenders with frontal panels, or large arch fenders are common.

- Bulk carriers and tankers: Usually berth very close to the quay or trestle for maximum crane or loading arm reach. Large panel systems with cone/cell fenders are typically used.

- Passenger and Ro-Ro vessels: Need smooth load transfer and controlled hull contact to protect ramps and gangways. Large, flat panel fenders with low reaction and good alignment are preferred.

Key vessel parameters include:

- Displacement or deadweight

- Approach speed and angle during berthing

- Hull form (e.g., flared bow, bulbous bow, flat sides)

- Freeboard range (light to fully loaded draft)

Fender systems designed for small fishing boats will not safely absorb the berthing energy of a large bulk carrier. The same berth cannot simply “reuse” the same fenders for all ship sizes without careful checking.

Berth Structure and Environmental Conditions

Coastal infrastructure and ecology are crucial. The conditions around a breakwater, pier, or jetty determine the danger of collision and the forces involved in the impact. Examples include tidal levels, wave factors, currents, and so on.

Similarly, the type and configuration of the structure are taken into consideration. For example:

- Open pile jetties and dolphins: Have limited face area and are more sensitive to concentrated loads. They often require fenders with larger frontal panels to spread contact pressure.

- Ports with large tidal ranges: Need fender lines with sufficient height or multiple fender levels so the ship always contacts the fender at safe zones over the whole tide.

- Harbors exposed to significant swell or long-period waves: Put fenders through many loading–unloading cycles. Fatigue and long-term performance of the fender body and its fixings become critical.

Environmental conditions directly affect fender size, height, layout, and materials.

Mooring Configuration and Approach

Vessels can be moored alongside in a variety of ways, depending on their requirements and construction. Therefore, how vessels come alongside the berth also matters:

- Side berthing (parallel to the quay): The most common case. The vessel contacts a line of fenders, and loads are distributed between multiple units.

- End berthing (bow or stern): Often seen at dolphins or specialized berths. The fender must match the hull shape (e.g., bulbous bow) to avoid local overstress.

- Dolphin and lock berthing: Contact points and angles can be very different from a straight quay wall. Fender location, height, and orientation must be adapted.

Approach speed, angle, tug assistance, and the presence of current or cross-wind all influence the design berthing energy and thus the fender selection.

Fender Type, And Arrangement

Consider the type, design, and arrangement of fenders in high-interaction areas. Harbor fenders are often organized in a line at more or less regular intervals. These fenders are found on the furthest reaches of the harbor, wharf, or trestle. There, they could come into contact with the ship’s hull. Rubber fenders are also installed on the side hulls of boats and ships, along the waterline and deck edges.

Thus, for harbors, fenders can be put as needed. Fenders, for the most part, are optional for big seagoing boats on the move. This is due to the absence of low-scale collisions in deep waters, as well as the effects of ship fenders on weight, stability, and speed.

Types of Fenders

Fenders in port vary significantly in size, shape, type, and style. Common types of fenders by shape include the following:

- Cylindrical fenders

- Spherical fenders

- Square fenders

- Corner fenders

- Round Fenders

- Conical fenders

- Circular fenders

- Arch Fender

- D-shaped fenders

Depending on their movement, there are many kinds:

- Fixed fenders

- Floating fenders

Fixed fenders, as the name implies, are attached to a structure like a ship or a harbor platform. A floating fender is suspended in the water and left to float. It serves as a buffer between two items, such as a vessel or a fixed structure.

Furthermore, fenders can be generically categorized into the following types based on their structure and design:

- Flatbed fenders

- Pneumatic fenders

- Foam fenders

Application Scenarios

Different fender types suit different applications:

- Quay walls and general cargo berths: Arch, cone, or cell fenders with or without panels, depending on vessel size.

- Oil and gas terminals, LNG, and chemical berths: Large cone or cell fenders with panels at the jetty, combined with pneumatic fenders for STS operations.

- Ro-Ro and ferry terminals: Large, flat panel fenders with low friction surfaces and controlled hull contact to support ramps and linkspans.

- Fishing ports, marinas, and small craft piers: D-type and cylindrical fenders, often bolted or chained directly to the quay or piles.

- Ship-to-ship transfer (STS): Large pneumatic or foam-filled fenders arranged between hulls to manage dynamic relative motion.

Matching fender type to real operating conditions is more important than simply choosing the largest or cheapest product.

Conclusion

Fenders in ports are not simple rubber blocks. They are engineered systems that protect both ships and berths by absorbing berthing energy and controlling reaction forces. Therefore, we should select a reputable marine equipment manufacturer.

Understanding the different types of marine fenders and their typical applications helps port operators, designers, and owners make better decisions. A well-chosen fender system increases safety, reduces damage and maintenance costs, and supports reliable marine operations over the long term.

FAQ

What is the main purpose of a port fender?

A port fender protects both the ship and the berth structure during berthing and mooring. It absorbs berthing energy and limits reaction forces so that neither side suffers unacceptable damage or deformation.

How is the required fender size and type determined?

Calculating berthing energy and the ship’s and berth’s permitted reaction tells you what size and type of fender to use. Engineers choose a fender that can safely absorb the energy with an appropriate reaction and contact pressure based on the vessel’s data (displacement, speed, and approach angle), the weather, and the constraints of the structure.

How often should port fenders be inspected and maintained?

Most ports carry out visual inspections at least once or twice per year, plus additional checks after storms, collisions, or major events. High-traffic or exposed berths may need more frequent inspections. A detailed inspection plan should cover rubber bodies, panels, chains, fixings, and the supporting structure.