Heavy Lifting Airbags

Efficient Solutions for Large Load Handling

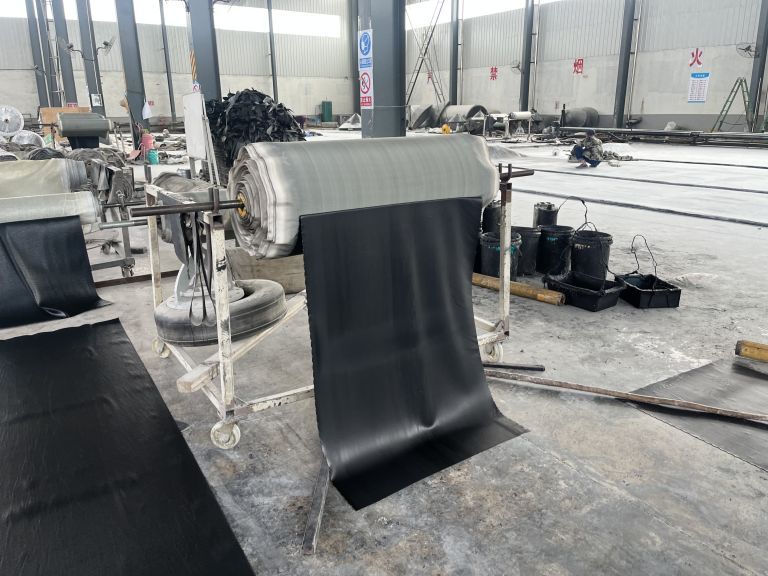

Henger’s Heavy lifting airbags are specialized tools designed to efficiently handle and transport large loads. It is widely used in industries. These are the industries where lifting large structures is common. Examples include shipbuilding, construction, and salvage. The airbags are made from tough materials, usually synthetic fibers or rubber-coated fabrics. They can withstand huge pressures and loads for many tough tasks.

Home » Marine Airbags » Heavy Lifting Airbags

Heavy Lifting Airbags introduction

Heavy duty lifting airbags are innovative tools designed to move and lift huge weights easily and safely. These airbags are made from strong materials such as synthetic tire cord plies and are known for their strength and durability. Each airbag has a maximum lifting capacity of 1,000 tons and a compression deformation rate of up to 70%. The airbags are available in diameters ranging from 0.8 to 3.0 meters and in lengths from 6 to 20 meters. This can be applied to all salvage and handling tasks.This technology is vital in industries that require lifting heavy weights. These include maritime, aerospace, and construction.

Heavy-duty lifting airbags use many layers of flexible but strong rubberized fabrics. They inflate to lift, push, pull, or hold loads. The principle of operation of these airbags is simple: a low-pressure, high-surface-area air cushion lifts heavy loads evenly, reducing the risk of damage. Unlike rigid lifting devices, heavy-duty lifting airbags can adapt to the shape of the load. They also spread the lifting force evenly over a large area.

Heavy duty lifting airbags are very different from other lifting solutions such as hydraulic jacks. Hydraulic jacks apply force in a small area. This can cause damage or stress on sensitive loads. In contrast, airbags provide a gentle force over a larger area. This approach reduces stress, increases stability, and improves the safety of the lifting operation.

These airbags play an important role in the launching and docking of ships, similar to the role of marine launching airbags.

They can be placed under the hull and inflated to lift the vessel for launching operations. When deflated, the airbags are very flat and require only 12 inches of width for quick installation. The ability to be quickly deployed and placed under the target greatly improves operational efficiency.

Heavy-duty lifting airbags are safer than traditional lifting methods. They distribute weight evenly and handle varying loads. Meet the requirements for use in a variety of environments.

Types and Models of Airbags

Heavy duty lifting airbags come in a variety of types and models. Each model is tailored to meet the specific needs of different industries and applications. The airbags range in size from small to large and vary in diameter. This allows them to handle a wide variety of projects. From lifting small machinery to relocating large structures such as ships or heavy equipment.

The capacity of these airbags varies greatly depending on the load requirements. Some airbags are designed for loads of just a few tons, while others can carry loads of hundreds of tons. The diversity of airbag capacities ensures a specialized lifting solution for all heavy lifting challenges. You can also choose airbag materials for the needed strength and flexibility. Henger offers a choice of materials including natural rubber, synthetic rubber, and tough fabrics. These materials resist punctures, abrasion, and harsh conditions.

These airbags also cater to customization to meet specific task requirements. They can be customized to specific lengths, diameters, and different layers to increase their load-carrying capacity and adaptability. Henger’s engineers enable industries to use airbags that meet their needs. They can also give custom advice based on your requirements.

Models include but are not limited to:

The standard model for general lifting tasks.

High-pressure models designed for higher load capacities.

Specialized models for special applications such as lifting in corrosive environments or extreme temperatures.

Heavy Lifting Airbag Specifications

Henger’s heavy duty lifting airbags are designed to meet strict performance standards. These standards are critical to safe and efficient operation. These airbags have varying lifting capacities, typically ranging from 10 tons per meter to over 40 tons per meter, depending on their size and construction. The working pressure of these airbags can be as high as 350kPa, enabling them to easily carry huge weights. The airbag’s load capacity is also important. It shows the most weight each airbag can carry without harm. Henger offers different types of airbag options depending on specific needs. Each model is designed for specific features. They match a variety of lifting conditions and requirements. This ensures optimal performance in each unique situation.

S1 Models: These are standard airbags for general lifting and moving tasks.

S2 Models: Designed for high-load applications, they are more robust and can handle heavier loads.

S3 Model: Airbags have ultra-high capacity. They provide the most lift and are very durable. They are for the most demanding tasks.

| Model | D(m) | P(Mpa) | Working Height(m) | Unit Bearing Capacity(ton/m) | |||||

| 0.4D | 0.5D | 0.6D | 0.4D | 0.5D | 0.6D | ||||

| S1 | S10 | 0.8 | 0.2 | 0.32 | 0.4 | 0.48 | 15.1 | 12.6 | 10 |

| 1 | 0.16 | 0.4 | 0.5 | 0.6 | 15.1 | 12.6 | 10 | ||

| 1.2 | 0.14 | 0.48 | 0.6 | 0.72 | 15.8 | 13.2 | 10.6 | ||

| 1.5 | 0.11 | 0.6 | 0.75 | 0.9 | 15.5 | 13 | 10.4 | ||

| S11 | 0.8 | 0.19 | 0.32 | 0.4 | 0.48 | 14.3 | 11.9 | 9.5 | |

| 1 | 0.15 | 0.4 | 0.5 | 0.6 | 14.1 | 11.8 | 9.4 | ||

| 1.2 | 0.13 | 0.48 | 0.6 | 0.72 | 14.7 | 12.2 | 9.8 | ||

| 1.5 | 0.1 | 0.6 | 0.75 | 0.9 | 14.1 | 11.8 | 9.4 | ||

| S12 | 0.8 | 0.24 | 0.32 | 0.4 | 0.48 | 18.1 | 15.1 | 12.1 | |

| 1 | 0.19 | 0.4 | 0.5 | 0.6 | 17.9 | 14.9 | 11.9 | ||

| 1.2 | 0.16 | 0.48 | 0.6 | 0.72 | 18.1 | 15.1 | 12.1 | ||

| 1.5 | 0.13 | 0.6 | 0.75 | 0.9 | 18.4 | 15.3 | 12.2 | ||

| 1.8 | 0.1 | 0.72 | 0.9 | 1.08 | 17 | 14.1 | 11.3 | ||

| S2 | S20 | 1 | 0.24 | 0.4 | 0.5 | 0.6 | 22.6 | 18.8 | 15.1 |

| 1.2 | 0.2 | 0.48 | 0.6 | 0.72 | 22.6 | 18.8 | 15.1 | ||

| 1.5 | 0.16 | 0.6 | 0.75 | 0.9 | 22.6 | 18.8 | 15.1 | ||

| 1.8 | 0.13 | 0.72 | 0.9 | 1.08 | 22 | 18.4 | 14.7 | ||

| 2 | 0.12 | 0.8 | 1 | 1.2 | 22.6 | 18.8 | 15.1 | ||

| S21 | 1 | 0.27 | 0.4 | 0.5 | 0.6 | 25.4 | 21.2 | 17 | |

| 1.2 | 0.23 | 0.48 | 0.6 | 0.72 | 26 | 21.7 | 17.3 | ||

| 1.5 | 0.18 | 0.6 | 0.75 | 0.9 | 25.4 | 21.2 | 17 | ||

| 1.8 | 0.15 | 0.72 | 0.9 | 1.08 | 25.4 | 21.2 | 17 | ||

| 2 | 0.14 | 0.8 | 1 | 1.2 | 26.4 | 22 | 17.6 | ||

| S22 | 1 | 0.31 | 0.4 | 0.5 | 0.6 | 29.2 | 24.3 | 19.5 | |

| 1.2 | 0.26 | 0.48 | 0.6 | 0.72 | 29.4 | 24..5 | 19.6 | ||

| 1.5 | 0.2 | 0.6 | 0.75 | 0.9 | 28.3 | 23.6 | 18.8 | ||

| 1.8 | 0.17 | 0.72 | 0.9 | 1.08 | 28.8 | 24 | 19.2 | ||

| 2 | 0.15 | 0.8 | 1 | 1.2 | 28.3 | 23.6 | 18.8 | ||

| 2.5 | 0.12 | 1 | 1.25 | 1.5 | 28.3 | 23.6 | 18.8 | ||

| S3 | S30 | 1 | 0.35 | 0.4 | 0.5 | 0.6 | 33 | 27.5 | 22 |

| 1.2 | 0.29 | 0.48 | 0.6 | 0.72 | 32.8 | 27.3 | 21.9 | ||

| 1.5 | 0.23 | 0.6 | 0.75 | 0.9 | 32.5 | 27.1 | 21.7 | ||

| 1.8 | 0.19 | 0.72 | 0.9 | 1.08 | 32.2 | 26.8 | 21.5 | ||

| 2 | 0.17 | 0.8 | 1 | 1.2 | 32 | 26.7 | 21.4 | ||

| 2.5 | 0.14 | 1 | 1.25 | 1.5 | 33 | 27.5 | 22 | ||

Advantages of using heavy lift airbags

There are several advantages to using heavy lift airbags supplied by Henger.

Cost Effectiveness:The availability of these airbags reduces the need for more expensive lifting machinery and reduces the labor costs associated with complex lifting setups.

Economical and Flexible: Lifting and handling with heavy lift Henkel airbags eliminates the need for chutes or carts, thus reducing construction costs. In addition, the low reaction force of the airbag on the object does not damage the structure.

Low reaction forces: Airbags spread the load over a larger area. This lowers stress on the lifted object compared to more rigid lifting methods.

Structural Safety: The gentle handling characteristics of airbags make them ideal for use on sensitive or fragile structures, reducing the risk of damage during the lifting process.

Ultra-high lifting capacity: HENGER’s airbags are capable of lifting caissons up to a maximum weight of 5,000 tons. Cofferdams can be lifted up to a maximum weight of 2,200 tons.

Strong & Durable:Our heavy duty lifting airbags are made of special synthetic tire cord, which is stronger than traditional boat launching airbags. The maximum working pressure can reach more than 350kPa, ensuring stable work in various harsh environments.

Applications for Heavy Duty Lifting Airbags

Henger’s Heavy Duty Lifting Airbags have a wide range of uses in a number of industries including construction, military and rescue.

Construction: Airbags are used to lift large building materials, align heavy structural components, and even assist in bridge construction or repair.

Military: Airbags are a quick, mobile way to set up or move large military installations and equipment.

Rescue Operations: In emergencies like building collapses or vehicle accidents, heavy lift airbags can be used. They safely and quickly lift heavy debris, giving rescue teams critical access.

These airbags also help move large vessels and heavy machinery. They are invaluable in industries where heavy and bulky items need to be relocated. Whether it’s moving a stranded vessel or positioning large machinery in a factory, heavy lift airbags provide a reliable and efficient lifting solution.

Maintenance Guidelines

Keeping heavy-lifting equipment airbags effective requires regular inspections and careful maintenance. To ensure optimum performance of these airbags, the following guidelines must be followed:

Regular Inspection: Inspect the airbag before and after each use for any signs of wear, tear or puncture. This is vital to prevent failure during operation.

Correct Storage: Store the airbag in a cool, dry place out of direct sunlight and sharp objects. UV exposure and extreme temperatures can degrade the material over time.

Cleaning Procedure: After use, wash the airbag with mild soap and water to remove any dirt or debris. Avoid harsh chemicals that can damage rubber or fabric.

Pressure Check: Periodically check air pressure with an accurate gauge to ensure that the airbag is inflated to the correct specifications for its intended use.

Handling: Always handle airbags with care and avoid dragging them over rough surfaces to avoid abrasion and weakening of the material.